AI technology revolutionizes environmental sustainability and product development. Companies can now reduce costs and improve their ecological footprint simultaneously. Smart algorithms analyze material properties, environmental impact, and production processes to help businesses make planet-friendly decisions that boost their bottom line.

AI-powered sustainable product design gives companies sophisticated tools that optimize resources without compromising quality. These solutions tap into huge databases of material properties and environmental data to pick options that work for both budgets and the environment. The systems also cut down raw material use and energy consumption,which leads to better profits.

Companies see benefits beyond just doing good for the planet. AI-enabled building systems energy use by up to 30%, while AI simulations create products that meet tough environmental rules. The numbers speak for themselves business leaders who combine AI with sustainability efforts earn 43% more than those who don’t.

This piece shows you how AI optimizes design, picks smart materials, and energy use throughout product lifecycles. These changes cut costs and boost environmental performance. You’ll learn about practical uses, real-life examples, and ways to balance profit with planet care in your product development.

AI-Driven Design Optimizations That Cut Product Costs

Image Source: LeewayHertz

Advanced design algorithms are changing how products are developed. They balance economical solutions with eco friendly outcomes. Companies now use computational innovation to create better products with fewer resources.

Generative Design for Lightweight Structures

Generative AI gives engineers multiple design options based on set parameters. Engineers can explore solutions that human designers might not think of on their own. Results have been impressive. Projects have shown greater than 10x reduction in development time and greater than 3x improvement in structural performance. This technology creates lightweight yet reliable structures that are vital for industries where weight affects environmental impact.

Industrial designers in the automotive sector have made progress. They created 25 versions of a next-generation car dashboard with detailed parts in just two hours. This process usually takes a full week. The faster design process lets teams spend more time on consumer testing. They can also focus on supplier checks and make designs better for manufacturing and sustainability.

Topology Optimization in Additive Manufacturing

AI algorithms make topology optimization better at distributing materials in design spaces. The Solid Isotropic Material with Penalization (SIMP) technique makes material distribution better step by step. It maximizes rigidity and reduces weight. Recent advances have created special approaches for additive manufacturing. These approaches eliminate overhangs greater than 45° and need fewer support structures.

New hybrid methods like SIMP TO-DL with conditional Generative Adversarial Networks (cGAN) work faster. They are 5000 times faster than traditional topology optimization . These methods achieve the same compliance with smaller volume fractions. Medical devices benefit from these techniques. They help create implants that reduce strain and stress shielding.

AI-Based Simulation to Reduce Prototyping Cycles

AI-powered virtual prototyping needs fewer physical tests. Digital simulations help engineers find design problems before making physical prototypes. This cuts development costs and gets products to market faster.

These simulations create a digital feedback loop. Engineers from different fields can work together on design changes at the same time. Product development cycles are up to 70% faster and cheaper. The process wastes less material throughout.

AI simulations in the automotive sector make prototyping better. They remove inefficiencies and waste that usually come with repeated testing. Complex transmission components show big savings. A single optimized casting session saves thousands of dollars in materials.

Reducing Material Waste Through Smart Selection

Smart material selection using AI marks a crucial step toward waste reduction. Manufacturers can now make green choices that maintain performance and profit margins.

AI-Powered Material Databases for Sustainable Products Design

AI algorithms analyze huge databases of material properties, environmental data, and detailed life cycle assessments. Engineers now get a complete picture of each material’s environmental costs. The construction industry needs this smart selection process since building activities make up 42% of primary energy use and 39% of worldwide greenhouse gas emissions. This becomes more crucial as embodied carbon will represent 50% of total emissions from new constructions by 2050. AI-driven databases that suggest optimal material combinations play a vital role in this transformation.

Predictive Analysis for Recyclable and Bio-Based Materials

Predictive modeling uses computing power to forecast how polymers perform and creates designs that recycle or biodegrade better. This method supports a circular polymer economy through data analysis of production, use, waste creation, and recycling rates. Machine learning algorithms help design materials that work well and end their life cycle appropriately. To cite an instance, AI-assisted biodegradable polyesters could reduce microplastics in our oceans. These technologies help companies:

- Optimize material selection for recyclability

- Speed up bio-based alternative development

- Predict environmental effects throughout the lifecycle

Lifecycle Assessment Integration in Early Design Stages

Design decisions made early determine about 70-80% of a product’s environmental impact . Traditional lifecycle assessments happen after detailed design completion when changes cost too much. Computing tools now provide quick environmental assessments during concept phases. CAD-integrated environmental tools like SolidWorks Sustainability and Autodesk Sustainability Workshop show how live assessment fits into design work. The automotive industry’s material-focused LCA integration has cut environmental effects by 25-35% compared to standard material choices. These tools make sustainability an essential part of creating new products.

Energy Efficiency Gains Across the Product Lifecycle

AI-powered energy efficiency solutions create major operational savings throughout the product lifecycle. AI makes up to-the-minute adjustments to energy usage patterns that go beyond design aspects. These adjustments create eco friendly systems that cut both costs and carbon footprints.

AI in HVAC and Smart Building Systems

Smart building climate control has transformed through AI analysis of sensor data to spot inefficiencies and optimize operations. Smart algorithms can predict future energy requirements and adjust ventilation based on how people use the space and outside conditions. Studies reveal that AI in HVAC systems cuts energy usage by 15-30% while keeping comfort levels at their best.

AI-driven systems in commercial buildings track and analyze internal and external data points to predict environmental changes. The system runs by itself and eliminates extra runtime. Companies report a 33.5% reduction in supply fan runtime and 62% reduction in heating stage runtime. The system also spots equipment running without need and open doors or windows. It quickly adjusts operations to stop energy waste.

Energy Consumption Forecasting in Manufacturing

Manufacturing plants use AI-powered forecasting models to predict and optimize energy needs with high accuracy. AI enables smart energy management by analyzing past patterns and external factors like weather. Research shows that factories using AI technologies see a significant decrease in energy intensity . This boost both productivity and energy efficiency at the same time.

Advanced forecasting models combine time series analysis, artificial neural networks, and ensemble methods. These models reveal consumption patterns that human operators might miss. Companies can buy energy exactly when needed. This cuts waste and operational costs by 10-25% across production sites.

AI-Optimized Logistics for Lower Emissions

Smart route planning stands out as AI’s direct impact on eco-friendly logistics. AI algorithms process big datasets of current traffic patterns, delivery times, and road slopes. They create routes that minimize fuel use and emissions. These improvements typically show:

- 15-30% reduction in miles driven through optimized multi-stop routing

- 20-40% decrease in idle time by avoiding traffic congestion

- 25-35% improvement in overall vehicle utilization rates

Smart demand forecasting helps plan loads better and combine deliveries to reduce empty trips. Logistics companies consistently cut emissions through these combined approaches without losing operational efficiency.

Balancing Cost Savings with Environmental Impact

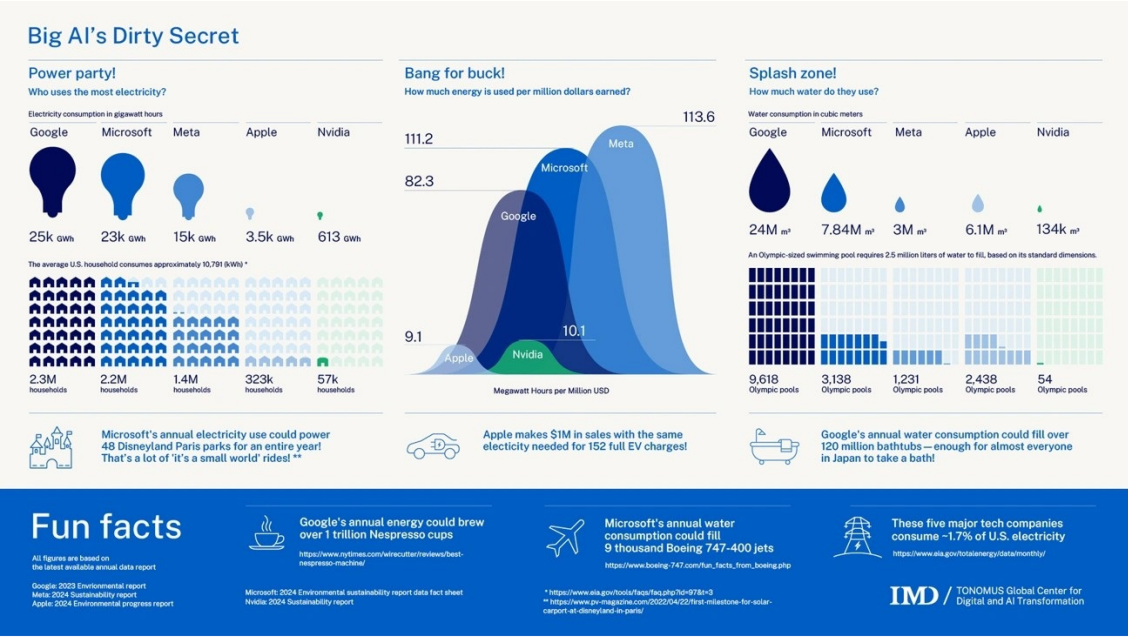

Image Source: IMD Business School

Companies face a major challenge in balancing economic viability with environmental responsibility as they roll out AI solutions. The success of sustainable initiatives depends on this delicate balance between cost and environmental impact.

40% Cost Reduction Standards in AI-Driven Projects

AI-powered profitable sustainability helps companies achieve remarkable gains in efficiency. The manufacturing sector now uses advanced solutions like carbon capture and analytics that first need investment but pay off well over time. Steel industry practices in recycling and material reuse save energy, lower emissions, and boost product quality. AI driven process optimization has shown cost reductions of up to 40% while reducing environmental effects, unlike traditional methods.

AI for Environmental Sustainability Examples in Packaging

AI revolutionizes packaging to address waste reduction and meet consumer expectations. A 2018 Tetra Pak survey revealed that 80% of South Korean and 74% of US consumers avoid products with excessive packaging. Companies like Johnson & Johnson, Amazon, and L’Oreal have responded to this need with sustainability targets—L’Oreal wants to cut plastic use by 50% by 2030. Manufacturers use AI solutions to develop eco-friendly materials and optimize package designs while keeping costs down.

Trade-offs: AI’s Own Energy and Resource Footprint

AI systems consume substantial resources despite their benefits. GPT-4’s training uses about 50 gigawatt-hours of electricity—enough to power San Francisco for three days. Data centers could use up to 1,050 terawatts by 2026, becoming the fifth largest electricity consumer worldwide. AI content generation’s power needs vary widely—a standard image takes about 1,141 joules, while a 5-second video needs approximately 3.4 million joules.

Using AI for Environmental Sustainability Without Greenwashing

AI enhances environmental monitoring by tracking iceberg changes and mapping deforestation effects better than humans. All the same, businesses must avoid false environmental claims. Organizations need to prove their environmental claims with reliable data that covers AI’s complete lifecycle from development through training to deployment. AI helps identify greenwashing through quick analysis of sustainability claims while helping companies make genuine environmental improvements.

Conclusion

AI for environmental sustainability marks a radical alteration in business approaches to product development. This piece shows how artificial intelligence creates an unlikely combination of major cost cuts and better ecological performance. These technologies go beyond simple expense reduction and revolutionize production processes while delivering real environmental benefits.

Companies using AI-driven design optimizations achieve amazing results. Development cycles run 70% faster. Structures perform 3x better. Material distributions get optimized through algorithms that work thousands of times quicker than traditional methods. On top of that, smart material selection systems analyze huge sustainability databases. Your team can make eco-friendly choices without sacrificing performance or profits.

Energy efficiency emerges as another key advantage. AI-powered systems cut HVAC energy use by 15-30%. They optimize manufacturing energy consumption by 10-25%. Smart route planning reduces logistics emissions by 15-40%. These improvements boost your bottom line and shrink your carbon footprint.

The business case for AI adoption becomes stronger as implementations mature. Companies cut costs up to 40% across manufacturing processes and meet growing consumer demand for eco-friendly practices. The numbers tell the story businesses that combine AI with sustainability initiatives earn 43% more profit than those that don’t.

Trade-offs exist, of course. AI systems’ computational needs consume substantial resources, and large models need significant energy inputs. But the net environmental benefit typically outweighs these costs with strategic implementation.

Your chance lies in finding the sweet spot between cost reduction and sustainability. AI-optimized processes let you share savings with customers while reinvesting in environmental improvements. This balanced approach positions your products competitively and shows real ecological commitment.

AI for environmental sustainability changes faster each day. Companies that adopt these technologies now will gain advantages through both cost leadership and environmental differentiation. The future belongs to businesses that apply AI solutions to address economic and ecological needs, creating truly sustainable growth.