AI-powered supplier collaboration systems are transforming retail operations by cutting costs throughout the supply chain. Businesses that employ AI in their supply chains typically reduce costs by 20% and increase revenue by 10%. It also helps companies achieve 65% higher service levels and 35% better inventory management.

These intelligent systems deliver the most important operational improvements. Your logistics costs can drop by 5-20% while operating costs decrease by up to 25%. AI-driven predictive analytics helps optimize stock levels, cut waste, and maintain product availability. Retail IT leaders understand this value, with 91% making AI their top technology priority by 2026.

Leading companies are already seeing benefits from supply chain collaboration. BMW and Samsung use AI to find risks, boost supplier performance, and streamline operations. These systems can boost demand forecast accuracy by up to 20% and minimize supply chain errors by 20% to 50%. This piece will show you how these intelligent collaboration platforms work, ways they reduce costs, and steps to implement them in your retail operation.

The Cost of Disconnected Supplier Systems in Retail

Data silos continue to be one of the oldest challenges retailers face today. These invisible barriers block data flow between systems and complicate daily operations that ended up hurting your bottom line. Retailers spend a lot on system upgrades but still face issues with disconnected supplier systems that prevent continuous collaboration.

84% of Executives Report Data Silos Affecting Decisions

The problem might look technical at first, but it has substantial business effects. A Harvard Business Review survey showed 84% of executives believe data silos negatively affect their daily decisions. Data from Salesforce’s 2024 Connectivity Report reveals 81% of IT leaders say these silos actively slow their digital transformation efforts. This creates a risky situation – you have more data than ever before, but its value stays locked in separate systems.

Retail silos demonstrate barriers between point-of-sale systems, inventory management, e- commerce platforms, and supplier data. A retailer might over-forecast demand during holiday season because e-voucher redemptions tracked in one system never synced with the supply chain management platform. Failed data synchronization causes wrong inventory calculations and excess stock in warehouses.

US $3.1 Trillion Lost Annually Due to Fragmented Data

Financial implications paint a grim picture. IDC estimates fragmented data costs the global economy US $3.1 trillion yearly. This represents the hidden tax organizations pay when operating with disconnected information systems. McKinsey’s research shows data silos cost businesses around $3.1 trillion each year in lost revenue and productivity.

Direct financial losses pile up alongside operational inefficiencies. About 60% of an organization’s data remains unknown or unavailable to people who need it. Customer trips become disjointed due to gaps in organizational knowledge. Teams handling different touchpoints lack the complete visibility needed to deliver informed and unified customer experiences.

Impact on Inventory, Forecasting, and Customer Experience

Disconnected supplier systems create several operational challenges:

- Inventory management failures: Split inventory data creates count inaccuracies, excess stock, and stockouts. Retailers struggle to optimize stock levels and fulfill orders quickly without centralized inventory visibility across channels and warehouses.

- Flawed demand forecasting: Separate silos cause slow inventory turns without a shared view across channels. Supply chain inefficiencies grow as multiple separate application delay real-time updates.

- Diminished customer satisfaction: Silos interfere with omnichannel participation and hurt customer satisfaction. Customers see conflicting product availability information when web-based and store-based systems don’t sync.

PYMNTS Intelligence report shows 63% of non-grocery retailers say siloed data stops them from responding to real-time demand changes. Delayed or unreliable insights miss opportunities while poor data quality damages credibility with leadership teams. Retailers can’t anticipate customer needs effectively without unified data—this leads to frustration and customer loss.

What Are AI-Powered Supplier Collaboration Systems?

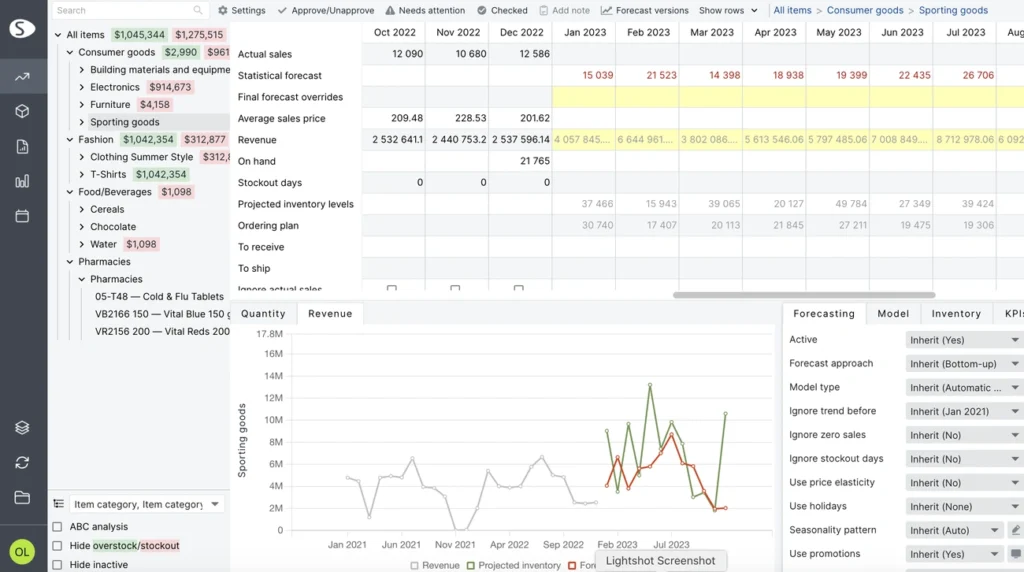

Image Source: GMDH Streamline

AI-powered platforms have transformed supplier collaboration systems beyond simple data exchanges. These smart systems help businesses save billions by connecting retailers and suppliers through data, analytics, and automation.

Definition and Core Components

AI-powered supplier collaboration systems let retailers and suppliers work together on secure, integrated platforms to share and analyze data. The global AI retail market will grow at a 23% annual rate through 2030, reaching $40.74 billion. These systems typically include:

- Data integration frameworks that connect disparate systems across organizational boundaries

- AI analytics engines that process information from multiple sources to generate applicable information

- Secure collaboration environments with configurable access controls

- Automated workflow tools that optimize operations between partners

These systems help manufacturers, distributors, and retailers work better together without exposing sensitive information. They make inventory management easier, arrange forecasts, and optimize coordination between internal teams and external partners.

Comparison with Traditional One-to-One Data Sharing

Old supplier collaboration methods used individual data contracts between partners. This created friction, legal costs, and long setup times. AI-powered systems bring several benefits:

They remove the hassle of managing separate agreements. They provide up-to-the-minute data analysis instead of waiting four-plus weeks for syndicated market reports. They also support collaboration between multiple parties rather than just two.

Brands used to ship products to retailers and wait for reorder signals. Now, retailers like Walmart give vendors platforms with daily updates on store-level sales and inventory. This helps suppliers understand customer demand. AI systems take this further by spotting patterns humans might miss.

Role of Clean Rooms in Privacy-Safe Collaboration

Clean rooms are the foundations of privacy-compliant supplier collaboration. These secure spaces let participants analyze combined datasets without exposing sensitive or personal data. They provide neutral, controlled environments for joint planning while keeping information confidential.

Data stays in one place with minimal duplication, so owners maintain a single source of truth. Companies value collaboration, but privacy remains crucial—80% of leading companies say up-to-the-minute data analysis matters for supply chain success. This explains why privacy-enhancing technologies keep growing.

Clean rooms help retailers and brands create valuable customer segments, measure marketing results, and understand inventory better. They study anonymous purchase histories and browsing patterns to identify groups like “value-conscious shoppers” or “brand loyalists”.

Unlike regular data-sharing tools that show detailed information, clean rooms block direct access while supporting complex analysis. This balance of usefulness and privacy makes them perfect for organizations working together in today’s data-sensitive retail world.

How AI Collaboration Systems Cut Retail Costs by 40%

Image Source: Lark

AI-powered supplier collaboration systems show clear benefits by connecting data and processes that were previously separate. Retailers who implement these technologies see dramatic cost reductions in their operations, inventory, and logistics.

Real-Time Inventory Visibility and Auto-Replenishment

Accurate, immediate inventory visibility creates the foundation for cutting costs in retail supply chains. Companies gain instant insights into product locations and quantities throughout their networks by implementing AI-powered tracking systems. These systems make use of RFID, IoT sensors, and cloud-based tracking to create a live dashboard of every unit—whether on a shelf, in a truck, or in transit.

AI takes this visibility further with intelligent restocking processes. The system automatically triggers new orders when inventory drops below set levels. This eliminates the need for manual checks and cuts down both stockouts and overstocking. Companies that use AI-driven replenishment have cut excess inventory by up to 35%.

AI-Powered Demand Forecasting Reduces Overstock

Better forecasting brings remarkable financial benefits. AI-improved demand forecasting cuts errors in supply chain networks by 30-50%, which leads to 65% fewer lost sales from stockouts. These systems look beyond historical sales data to analyze market trends, weather patterns, social media sentiment, and competitor activities.

Precise AI forecasting leads directly to better inventory management. Studies show warehousing costs drop by 5-10%, while administration costs fall by 25-40%. Retailers using advanced AI see up to 7% better forecast accuracy within six months, which results in 17% less overstock and 16% better inventory turnover.

Supplier Risk Prediction and Early Intervention

AI collaboration systems help save costs through proactive risk management. AI algorithms spot potential disruptions before they affect operations by analyzing supplier performance data, market trends, and external risk factors. This early warning system lets companies act quickly and plan alternatives.

Modern risk monitoring platforms look at recent incidents, operational details, financial stability, and cybersecurity risks to evaluate suppliers. Companies can avoid getting pricey disruptions and keep business running smoothly. DHL’s AI-powered forecasting system proves this point—it has cut delivery times by 25% across 220 countries while achieving 95% prediction accuracy.

Reduced Manual Work via Smart Contract Automation

Smart contracts in supplier systems streamline repetitive tasks like payments, inventory updates, and order processing. This cuts down manual work, reduces errors, and speeds up transactions. These contracts run automatically once programmed with agreed conditions—cutting delays and labor costs.

Supply chains become more efficient as smart contracts update inventory levels automatically as goods move through the system. New stock levels reflect immediately in inventory systems when shipments arrive at warehouses. A global manufacturer’s smart contract implementation led to 30% faster order-to-delivery times.

Case Study: ADEO’s 35% Reduction in Product Data Errors

ADEO struggled with product data management because suppliers and central teams entered product information manually, which created incomplete or inconsistent data. The company teamed up with AI specialists to create solutions that automate product classification and attribute extraction.

The results proved remarkable. The automated data processing reduced errors by 35%. The system achieved 96% accuracy for 63% of products. It now handles 3,600 different product categories and manages over 85,000 attribute values. Better product data quality boosts e- commerce success rates since incomplete product information can cut conversions by up to 50%.

Ready to see how much you could save? Get our free small business pricing calculator and discover your potential savings today.

Governance and Interoperability as Enablers

The success of supplier collaboration systems relies on core elements that go beyond just technology. A solid governance framework and interoperability standards build the backbone that helps these systems become flexible and deliver significant cost savings.

Shared Data Models and Standardized Schemas

Standard data models remove friction in supplier collaboration by giving all participants a common language. Companies risk errors and inefficiencies during data exchange without consistent schemas. A standard structure helps retailers coordinate information that gives suppliers a consistent view while keeping retailer-specific details.

The Object Management Group (OMG) provides standardized XML schemas specifically built for retail environments. These schemas help applications combine smoothly across retail ecosystems. Adobe’s Experience Data Model offers standardized data structures for retail that adapt to specific business needs.

Cross-Functional Teams for Unified Collaboration

Cross-functional teams play a vital role in successful collaboration beyond technology. These teams bring together experts from IT, operations, marketing, and supply chain management to create solutions that match business goals. Retail teams find it hard to improve efficiencies between functional areas when they work in isolated applications.

Cross-functional collaboration affects business results directly—a billion-dollar retailer could generate $10 million in extra sales by improving planogram compliance by 20% through better team execution. These collaborative structures also promote innovation as different views help solve complex challenges and reveal new opportunities.

Clean Data and Ownership Rules for Scaling

Clean, well-governed data builds the foundation to scale supplier collaboration systems. Data cleaning spots and fixes errors before they spread throughout the ecosystem. Clear documentation for cleaning logic, ownership, and business definitions helps teams start faster and reduces confusion when requirements change.

Ownership rules become critical as collaboration grows. McKinsey points out that successful data-based collaboration needs awareness of data’s relative value, consistent ontology, quality assurance processes, and secure sharing capabilities. An impartial “trustee” can help create fair arrangements when sharing value from collaborative efforts.

Scaling with AI: From MVPs to Ecosystem-Wide Adoption

Major retailers are taking their AI projects to the next level. They’re moving beyond small test cases to company-wide systems that show amazing results. Their progress from basic products to full-scale deployments shows how supplier collaboration systems create real value.

AI-Driven Campaign Optimization in Retail Media

AI algorithms automate retail media campaigns on multiple channels. These systems adjust bid strategies, pacing, and creative rotation automatically. Decision-makers believe AI will give better insights and recommendations, with 55% already using it to optimize their campaigns in real-time. Microsoft Azure OpenAI Service users can turn thousands of customer reviews into brief summaries. This helps boost SEO and gives potential buyers valuable product information.

Nestlé’s SISO Platform for Sell-In/Sell-Out Alignment

Nestlé built an AI-powered platform called SISO (Sell-In Sell-Out) to work better with major food retailers in Brazil. The platform connects sell-in and sell-out data through AI and data science. This helped Nestlé improve demand forecasting and logistics, which cut stockouts by up to 35%. The company’s marketing efficiency jumped by 57% after they brought in over 1,000 digital specialists.

ADEO’s AI Classification Across 85,000 Attributes

ADEO, Leroy Merlin’s parent company, struggled with messy product data from their suppliers. Their AI system now handles 3,600 categories and 85,000 attributes, with over 96% precision for 63% of products. The system cut product information errors by 35%. This meant fewer manual fixes and faster communication between suppliers, central teams, and digital channels.

Huawei Supplier Collaboration System: A Scalable Model

Huawei’s Supply Chain Collaboration (SCC) system creates instant communication between supplier demand and supply. This ensures stability and on-time delivery. The company manages suppliers through detailed certification standards that cover seven areas: quality, technology, response, cost, delivery, social responsibility, and environmental protection. Download our free small business pricing calculator to estimate the efficiency gains you could achieve with similar AI-powered supplier collaboration systems.

Conclusion

AI-powered supplier collaboration systems revolutionize retail operations beyond simple tech upgrades. Data silos cost the global economy $3.1 trillion annually, and this piece shows how these systems tackle this expensive problem.

Smart systems deliver impressive results in retail operations. Immediate inventory tracking with auto-replenishment cuts excess inventory by up to 35%. AI-improved demand forecasting cuts errors by 30-50% and reduces lost sales from stockouts by 65%.

Your business can tap into proactive risk management these systems provide. You get valuable time to create backup plans by spotting disruptions early, before they hit your operations. Smart contract automation also cuts down repetitive tasks and reduces errors.

ADEO, Nestlé, and Huawei show these technologies at work. ADEO cut product data errors by 35%, while Nestlé’s SISO platform reduced stockouts by up to 35%. These examples prove that good implementation saves substantial costs.