Every retailer faces the same critical challenge: inventory decisions that make or break profitability. Too much stock ties up capital and drives holding costs through the roof. Too little stock means lost sales and frustrated customers.

Nearly two-thirds (67%) of middle-market leaders acknowledge they need external expertise to fully harness AI in their operations. The reality is clear—retail supply chain software with AI capabilities offers one of the most powerful applications for cutting inventory costs while boosting operational efficiency.

We see how AI-powered supply chain tools enable retailers to build more sustainable operations. These systems change how you manage inventory, collaborate with suppliers, and respond to market shifts. The ability to analyze massive data sets in real time means retail supply chain management software helps you make smarter decisions that directly impact profits. Beyond basic analytics, these systems spot early-warning signals of supplier distress, analyze historical performance to predict delivery delays, and create visibility across your entire procurement network.

This article shows you exactly how AI-enabled forecasting delivers predictive insights from historical data and market trends. You’ll understand why leading retail supply chain software companies integrate AI into their platforms, and see specific use cases that demonstrate the evolution of supply chain management in consumer goods. Most importantly, you’ll discover practical implementation strategies to achieve significant inventory cost reductions in your own operations.

Building a Data-Driven Retail Supply Chain

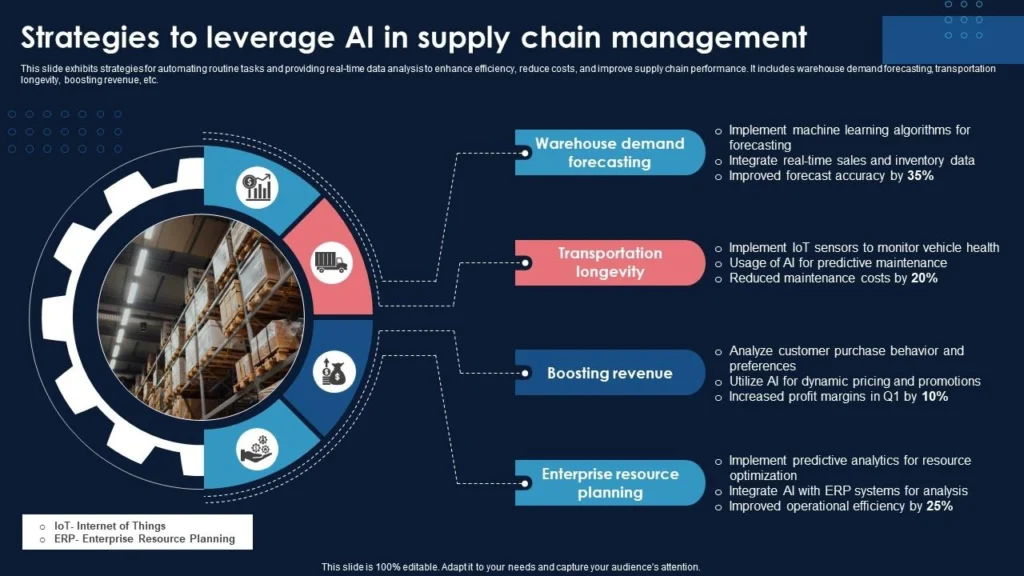

Image Source: SlideTeam

Success in retail starts with data foundations that support advanced AI applications. Building a data-driven retail supply chain means connecting disconnected systems to create complete visibility across your operation.

Creating a digital twin for inventory visibility

Digital twins function as virtual replicas of your physical supply chain, modeling assets, warehouses, logistics, inventory positions, and processes within a connected environment. This technology delivers a complete view of your retail ecosystem, identifying bottlenecks and demand curves within seconds. Early adopters report impressive results—CAPEX reductions up to 10%, sustainable inventory reductions up to 5%, and EBITDA improvements of one to three percentage points.

Digital twins go beyond static reports or dashboards. They create dynamic environments where you simulate potential scenarios before implementing real-world decisions. Retail supply chain software companies use this capability to test and refine AI-powered optimization strategies without operational disruption.

Integrating IoT and vendor portals into unified data layers

IoT devices enhance retail supply chain management software by automating data collection throughout operations. Smart shelves, RFID tags, and sensors track inventory levels across multiple locations in real time, enabling automated replenishment systems that reorder stock when levels drop below predefined thresholds.

These technologies require unified data platforms that eliminate traditional silos. Retailers typically operate across complex data ecosystems: ERP systems, inventory management platforms, CRM tools, and vendor portals. Modern retail supply chain software development services create integrated platforms connecting these systems, replacing manual processes like spreadsheets and disconnected portals with streamlined, automated workflows.

Using external market data for demand signals

Demand sensing represents a critical advancement in supply chain management for consumer goods. External market data—economic indicators, weather patterns, social trends, and events data—makes your forecasting dramatically more accurate.

Organizations that successfully integrate external data improve forecast accuracy by up to 28% and reduce inventory costs by 15%. This approach combines AI-backed sensing with human-directed learning and customization. Oracle retail supply chain software and other leading platforms incorporate these capabilities, helping you identify priority indicators most relevant to your specific business and product categories.

This integrated data approach transforms your retail supply chain from reactive operations into predictive ecosystems capable of anticipating and responding to market changes before they impact your bottom line.

8 AI Use Cases That Cut Inventory Costs by 35%

Image Source: Neudesic

AI implementation across retail supply chain functions delivers measurable inventory cost reductions. These eight applications generate the most significant financial impact for retailers ready to optimize their operations.

1. Predictive demand forecasting using historical and real-time data

Advanced forecasting systems analyze comprehensive data sets—past sales, customer behavior, market trends—to predict future demand with precision. Results speak for themselves: forecasting errors drop 20% to 50%, inventories lean out by 20% to 30%, and stockouts plummet up to 65%. Modern retail supply chain software enables proactive planning rather than reactive firefighting.

2. AI-powered inventory rebalancing across store networks

Smart inventory optimization moves stock between locations based on real-time demand signals. Products end up where they’ll sell best, maximizing full-price sell-through while cutting lost sales 20-30%. Systems like Rebalance.io spot emerging demand patterns before they hurt sales, preventing costly inventory imbalances.

3. Dynamic production scheduling with cost and emissions optimization

Sophisticated scheduling algorithms juggle multiple constraints at once—labor, equipment, materials, energy—to optimize production efficiency. Overall operational efficiency improves up to 20% through optimized family setups and mixed-technology assembly lines. Production disruptions trigger instant recalculation of optimal sequences.

4. Supplier risk detection using Tier-n visibility

Deep supply network visibility catches risks early across your entire supplier ecosystem. AI-powered systems monitor global events, score supplier vulnerabilities, and deliver real-time insights to prevent disruptions before they escalate. This creates practical visibility into critical components beyond first-tier suppliers.

5. Real-time logistics optimization for last-mile delivery

Last-mile delivery consumes 41–53% of total logistics costs. AI-driven route optimization delivers 15-25% fuel savings, 20-30% higher on-time deliveries, and up to 40% fewer failed attempts. Systems continuously monitor conditions and reroute deliveries instantly.

6. Auto-replenishment systems with minimum/maximum thresholds

Automated replenishment monitors inventory levels and triggers reorders when stock hits predetermined thresholds. Manual purchasing administration drops up to 50% while preventing both stockouts and overstocks. The minimum/maximum model excels for items with predictable demand patterns.

7. AI-driven markdown and discount planning

Smart markdown optimization analyzes price elasticity for individual products, determining optimal discount timing and depth. This precision drives 2-4% higher gross margin dollars while accelerating inventory turnover. Systems like MarkSmart™ turn reactive discounting into strategic profit optimization.

8. Smart contract automation for supplier compliance

Blockchain-powered smart contracts automate agreement execution without human intervention. Self-executing contracts enforce compliance rules directly in code, triggering penalties or adjustments when suppliers miss standards. Operations accelerate, compliance risk drops, transparency increases.

Ready to see how much you could save? Take our free Profit Pulse Audit to identify inventory optimization opportunities in your retail supply chain.

Implementing AI in Retail Supply Chain Software

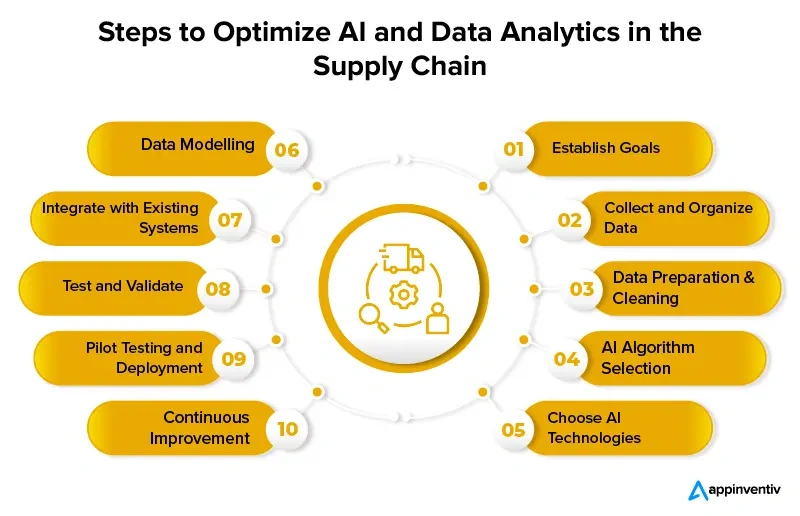

Image Source: Appinventiv

Smart implementation of AI in retail supply chains demands strategic technology choices and methodical deployment approaches. The path you choose determines both your timeline to results and long-term scalability.

Choosing between custom retail supply chain software development services and off-the-shelf tools

Your supply chain’s unique structure drives this critical decision. Custom systems deliver tailored optimization but demand significant upfront investment ($100,000-$400,000). Off-the-shelf software provides faster deployment with lower initial costs, though total ownership expenses can exceed expectations by 40%.

Key factors shape your choice: existing IT infrastructure, integration complexity, and in-house technical capabilities. Companies with standardized operations often succeed with off-the-shelf solutions. Those with complex, differentiated supply chains typically require custom development to capture their competitive advantages.

Evaluating Oracle retail supply chain software vs. other platforms

Oracle’s retail solutions embed AI Foundation for analytical insights that drive planning and inventory decisions. Their forecasting engine adapts to trends, seasonality, and promotions while applying machine learning.

Consider your AI strategy position: “taker” (user of existing tools), “shaper” (integrator of models with proprietary data), or “maker” (builder of foundation models). This framework guides platform selection based on your technical resources and competitive differentiation goals.

Running pilot programs to validate AI models

Define clear objectives and metrics aligned with business outcomes first. Build proofs-of-concept to validate AI applications before full deployment. Successful pilots focus on one or two high-value use cases deliverable within 3-4 months.

Document every learning to create scaling playbooks. This disciplined approach prevents costly mistakes during broader rollouts and builds internal confidence in AI capabilities.

Ensuring scalability and adaptability in deployment

Design modular AI architecture that supports switching between different models as needs evolve. Establish standardized processes and foster continuous improvement culture for sustainable technology integration.

Deploy edge devices where appropriate to process data locally, enabling greater operational agility. This distributed approach reduces latency and improves system resilience across your supply chain network.

Measuring ROI and Sustaining AI-Driven Gains

Your AI investment demands rigorous measurement to prove its worth. Smart tracking converts technology advances into concrete business results, ensuring value extends far beyond initial deployment.

Tracking inventory turnover and holding cost metrics

Inventory turnover ratio reveals how efficiently you sell through and replenish stock over time. This efficiency metric divides cost of goods sold by average inventory value. Strong turnover ratios signal healthy sales or smart purchasing, while weak ratios often indicate overstocking or sluggish demand. Benchmark against competitors in your retail vertical for meaningful comparison.

Holding costs represent 20-30% of total inventory value. These expenses include capital, storage, labor, security, equipment, and opportunity costs. Advanced forecasting algorithms and just-in-time practices cut these costs without sacrificing service levels.

Monitoring OTIF (on-time in-full) performance improvements

OTIF tracks the percentage of orders delivered with correct quantities on schedule. Major retailers like Walmart demand 98% OTIF performance, imposing penalties up to 3% of cost of goods sold for failures. Real-time visibility solutions boost OTIF scores by 5-10%. Shared data sets create a “single version of truth” across your entire supply chain network.

Establishing feedback loops for continuous model training

AI systems improve through continuous learning, making ongoing ROI assessment crucial. Build feedback mechanisms that capture performance data and refine models constantly. Focus on outcomes over outputs—measure meaningful business objectives that adapt with your operations.

Discover your potential ROI with our free Profit Pulse Audit – a detailed assessment of your retail supply chain’s efficiency and cost-saving opportunities.

Conclusion

AI-powered retail supply chain software delivers measurable inventory cost reductions—that’s not a promise, it’s a proven reality. You’ve seen the data: digital twins create visibility that cuts CAPEX by 10%, predictive forecasting reduces errors by 20-50%, and automated systems slash manual administration by half.

The eight use cases presented here aren’t theoretical applications. They represent immediate opportunities to cut inventory costs by 35% while building competitive advantages that compound over time. Your forecasting becomes more accurate, logistics more efficient, and replenishment more intelligent.

Success hinges on making smart implementation choices. Custom solutions offer precision but demand significant investment. Off-the-shelf platforms provide speed but may lack specificity. Pilot programs reduce risk and validate returns before full commitment.

Performance measurement separates successful deployments from expensive experiments. Track inventory turnover, monitor holding costs, and watch OTIF scores improve by 5-10%. These metrics prove AI’s impact on your bottom line.

Companies that master AI-driven supply chains gain advantages beyond cost savings. You anticipate market shifts instead of reacting to them. You prevent disruptions rather than managing crises. You optimize operations while competitors struggle with manual processes.

The window for early adoption advantage won’t stay open indefinitely. Every month you delay implementation is another month competitors could be capturing market share with superior efficiency and lower costs.

Your retail supply chain contains untapped profit potential right now. The question isn’t whether AI will reshape supply chain management—it already has. The question is how quickly you’ll harness these capabilities to unlock your competitive edge.

Key Takeaways

AI-powered retail supply chain software delivers measurable results through data-driven optimization and predictive analytics that transform traditional inventory management into strategic competitive advantages.

• AI reduces inventory costs by 35% through predictive forecasting, automated rebalancing, and real-time optimization across eight key use cases • Digital twins and IoT integration create unified data platforms that improve forecast accuracy by 28% and reduce stockouts by up to 65%

• Successful implementation requires pilot programs, proper platform selection, and continuous performance monitoring through OTIF and turnover metrics • Auto-replenishment systems and smart contracts reduce manual administration by 50% while preventing both overstocks and compliance issues

The transformation from reactive to predictive supply chain management represents more than cost savings—it creates sustainable competitive advantages through improved customer satisfaction, reduced waste, and enhanced operational agility in an increasingly complex retail environment.